Methanol Fuels

Methanol can be made from natural gas, from coal, from any organic wastes, from algae, etc. It can also be made from hydrogen and carbon dioxide. Thus, it can be made, and is made, now, from both natural gas and from coal. It is also being made in the laboratory from H2 and CO2 -- i.e., totally renewably and total zero carbon.We will have to start using methanol from natural gas, but to eventually move it to its deserved renewable status, renewable methanol be recognized on an equal footing with second generation ethanol (cellulosic ethanol).

Why we will need and want to go the use of methanol and methanol/ethanol/gasoline blends

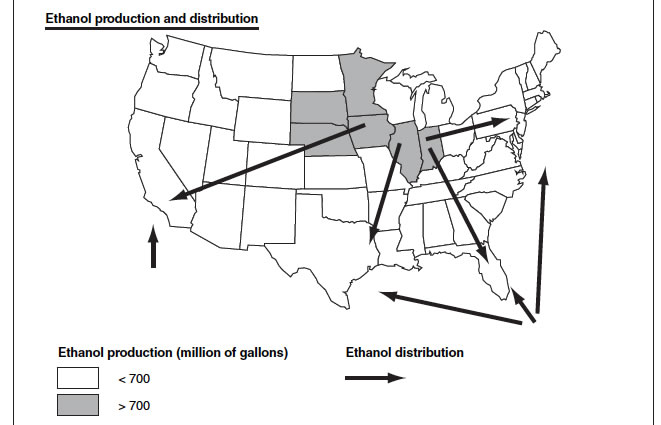

1. We can not make enough ethanol from corn to meet the current national requirement. See the Ethanol Blend Wall in our Ethanol Fuels Section.

2. We may be decades away from making enough cellulosic ethanol -- To be elaborated on.

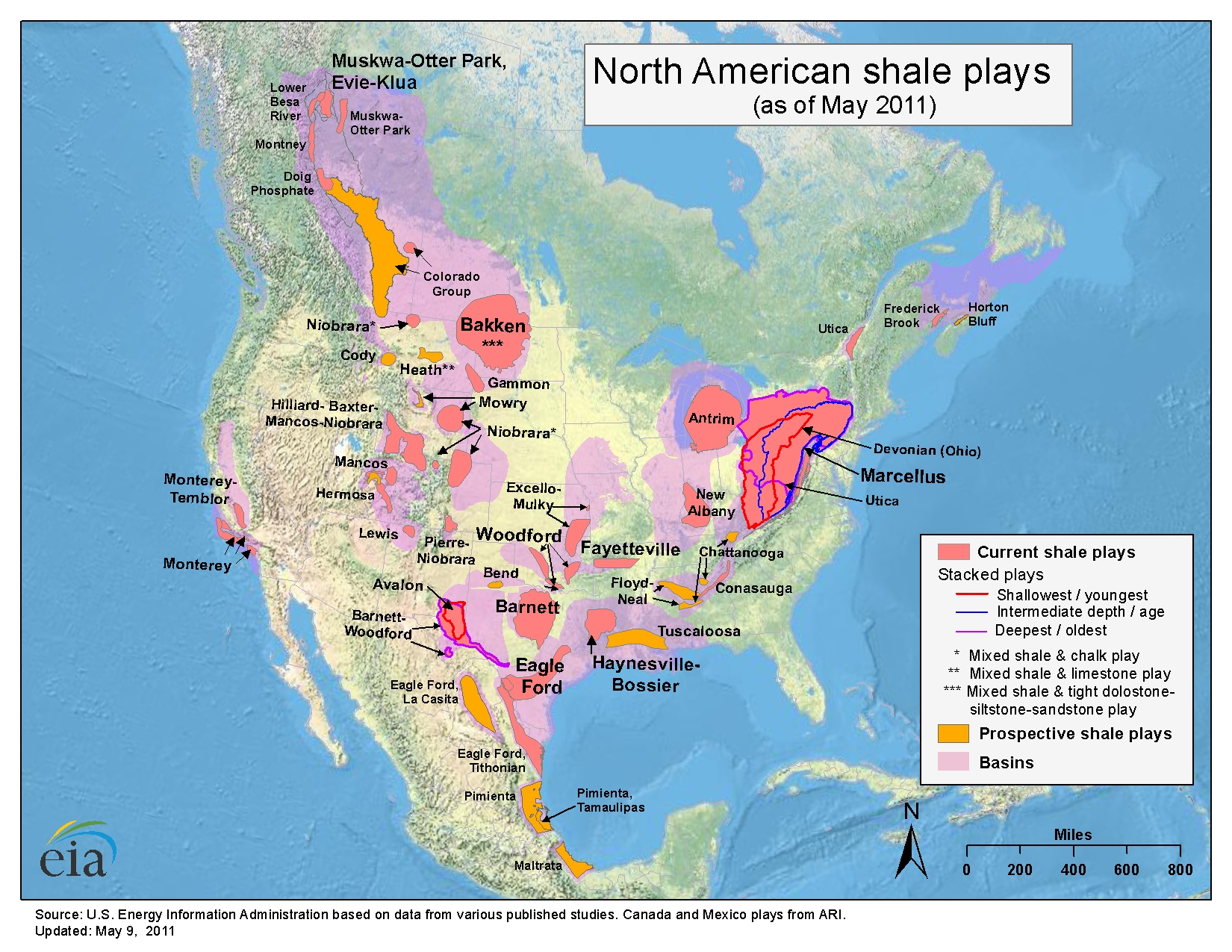

3. We have the natural gas resources needed to make methanol. See our Domestic Natural Gas and our Renewable Energy/Bio-Fuels pages.

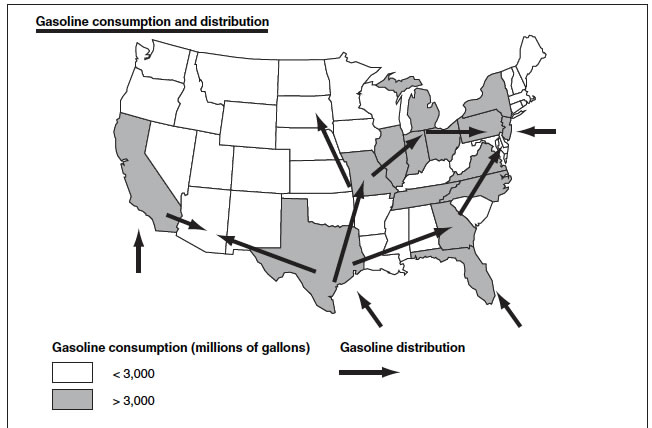

4. Methanol Distribution will be easier than ethanol, and even gasoline distribution.Gasoline distribution.

Ethanol distribution: essential from the mid-west, and Overseas.

Potential methanol plants and production can be distributed all over the US as they can be located near to the Natural Gas deposits.

Methanol from Organic wastes (Corn husks, mill wastes, food wastes, animal manure, etc.)

Very much in a way that we think about how good cellulosic ethanol would be if we could make it economically, making methanol from organic wastes is a real economic proposition now!

Methanol From Natural Gas

A very large amount of methanol is made world wide. The Methanol Institute is a very good source of information on these statistics and many other aspect of methanol.

The California Methanol Fuels Experiment

This very successful experiment, on our own soil, gets it own page. Link to California methanol fuel experience.

Chinese Methanol usage.

The most often voiced objection to methanol fuel

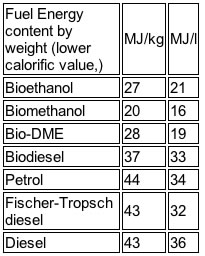

This is the low energy content of the fuel relative to gasoline.

However, there is more tot he story. The major additional asset methanol has is its high octane number (110). Its octane number is so high that we can run just as far to the gallon even though the energy content is only half that of petrol (see above).

Methanol can with current automotive engines easily replace 30% of gasoline and it is easy to make a motor for pure methanol, according to the Danish Methanol Association. We will investigate this further.

But first, note that both the US EPA and Saab Motors showed that the higher thermodynamic efficiency that an engine is able to run at enables it to compensate for its lower energy per unit volume.

An extensive look at the situation actually shows the remarkable value of methanol.

Mehanol at its best

“…The impact on the temperature decrease by alcohol fuels is significantly higher than for petrol. In the ethanol case, it is a reduction of 138 K [Kelvin] and for the methanol even higher (246 K). This improves the anti-knock properties substantially to the level of equivalent to an octane number of 129 in the ethanol case [and Research Octane Number 133 for methanol]. If this feature was utilised on a turbocharged engine to increase power density and further on for downsizing of the engine to reach the baseline power and performance, the two reports cited have calculated that the energy consumption could be reduced by some 25 % compared to a conventional petrol engine. The gain of 25 % is roughly equivalent to the relative difference between petrol and diesel engines in such vehicles. Bearing in mind that the average (relative) increase in efficiency of the engine has been about 0,5 % per year over the last 75 years or so, an improvement of this magnitude would be monumental.”

“Brusstar and co-workers conducted a study of great interest for future engine development of alcohol-fuelled engines (Brusstar et al., 2002). A 1,9 litre VW TDI diesel engine was used in these experiments. Engine modifications included port fuel injection and spark ignition. Cooled EGR [Exhaust Gas Recirculation] using a low-pressure long route (after turbine to before compressor) EGR system was used instead of the standard EGR system. Compression ratios between 17:1 and 22:1 were tested but the nominal compression ratio of 19,5:1 was used during most of the test series.”

“The methanol-fuelled engine had a peak efficiency of nearly 43 %, i.e. higher than the diesel-fuelled baseline engine, and the high-efficiency range was also broader than in the diesel case. Fuelled by ethanol, the engine had comparable peak efficiency to the diesel-fuelled engine. The knock sensitivity when operating on ethanol prevented the engine from achieving as high efficiency as when it was run on methanol.”

In the figure below the efficiency maps of the engine running on methanol and diesel is seen. BMEP stands for Brake Mean Effective Pressure and RPM stands for Revolutions Per Minute. The brake efficiency exceeded 40% over a power range of 12 to 75 kW for the methanol fueled engine.

(An exhaust characterisation study based on regulated and unregulated tailpipe and evaporative emissions from bi-fuel and flexi-fuel light-duty passenger cars fuelled by petrol (E5), bioethanol (E70, E85) and biogas tested at ambient temperatures of +22°C and – 7°C, Westerholm, Ahlvik & Karlsson, March 2008, p. 14-16).

So we could replace both gasoline and diesel fuel using methanol.

.