Natural Gas As a Fuel

Of course, natural gas has been the most widely used alternative fuel in the US, and only now ethanol in high blends (E-85) may be catching up, because there are over 2200 E85 filling stations. This page will discuss ways it is processed and used, as well as the reasons it will remain a niche fuel for fleets that return to their bases. It will point to the value of its chemical conversion to methanol and ethanol.

We have reviewed the supply of natural gas, here and here, and have discussed how its main ingredient, methane, can also readily be made from all kinds of wastes, i.e., that is methane is a renewable energy source, that results in very low Well-to-Wheel (WTW) net greenhouse gases being produced. Here we discuss natural gases use as a fuel, and maybe you will not be surprised to find out that our Energy Resourcefulness approach finds that it is best used to make liquid alcohol fuel. We briefly indicate its long history, its cleaner emissions and its ability to propel the largest vehicles. We will then review the pros and cons of the economics of having the nation convert its vehicles to using natural gas, and see that staying with a alternative liquid fuel will be a better way.

1. Historical Use of Natural Gas in Transportation

We are all familiar with natural gas propelled city buses. They have been with us for decades. Modern versions work very well. Some of us may know about natural gas propelled taxis and even scene some large trucks. In all these cases the vehicle go bask to a central location to fill up. Over the past decade Honda Motors has made a natural gas version of their popular 'Civic'. But its average yearly sales is around a 1000 cars/yr. It also has no problems with maintenance, but so few people have bought them for three very good reasons. First is that they cost about $10,000 more than a gasoline Civic. Second, they get half the range on a fill up. And, natural gas tanks are so expensive and so bulky, that if you can't put them on the roof (like a bus) there is no room for them. Third, the availability of filling stations is very limited.

So, if we are to use our natural gas in this manner these 3 limiting factors need to be removed. What is the cost of doing this? We address this in the next section.

1.1. Vehicles that return to a depot

But first we want to discuss the most successful application of CNG. This has been for buses.

2. Should we just compress it (called CNG) and convert our vehicles to run on CNG?

We must make use of our resource of fossil natural gas to start the process of getting us off oil. Because of the amount of oil we use, there is no other resource that we have in sufficient quantities today that can do it, except coal. But, as we discuss in our plan, this is must be seen as only the first transition step, as we must turn to using our wastes (and even growing algae to supplement these wastes for our fuel needs), if we are to sustainably proceed and not warm the atmosphere to critical levels.

As it turns out, concluding whether we should directly use the natural gas (as CNG or LNG) is primarily an economic issue, but secondarily a Greenhouse Gas issue. We discuss these next.

2.1. The economic issues

The costs of converting our fleet of vehicles to using natural gas is pretty well defined. Here we go over it, but the bottom line is that it would be very costly, something like a 1/4 of our gross national product. This is not possible to add this burden on our economy. Furthermore, the argument that we can refill in our homes is also a very expensive proposition, we review below.

Thankfully, there is an inexpensive way to get off oil and actually do a better job.

2.1.1.The conversion numbers look like:

The numbers are – on a retail basis – 235,000,000 light duty vehicles times $10,000/vehicle + 20,000,000 heavy duty vehicles times $50,000 (averaging over classes) = $3,350,000,000,000. Plus 130,000 filling stations * 500,000 (1 fast fill) = $65,000,000,000. Total cost to move off oil is thus $3,415,000,000,000. Plus or minus 10% this is approaching ¼ of our gross national product (or, if you like ¼ of our national debt). This is extremely unlikely to occur.

What does the alternative of converting natural gas to methanol, and installing methanol dispensers? If vehicles were allowed to run on methanol (which is cheaper than gasoline) the numbers look like: a cost increment of $100/vehicle and $25000 per filling station (to convert a pump to alcohol) the cost to the country would be 255,000,000*$100 + 130000*$25000 = $28,750,000,000 or 118th the cost of converting to CNG. This is a cost more in line with real possibilities – for example, it is about the amount that GM still owes the US on the loan we gave it. There is more to this approach before we get a final answer, because the production of methanol from natural gas is currently between 65 and 70% efficient. Thus, using 40% methanol tuned vehicle efficiency and 65% methanol production efficiency we would have a WTW efficiency of .4*.65 = 26%. Again in the range of gasoline or natural gas propelled vehicles, BUT with a big difference. It is estimated that it would require $100 more to make a vehicle run on methanol (vs. the $10,000 for natural gas or electric vehicles). And, we would incur much lower infrastructure costs, and with larger gas tanks in the vehicles, no inherent range limitations.

2.1.2. The natural gas pipeline distribution system is inadequate.

Another point that has not been discussed so far, is that the natural gas pipeline distribution system, which maybe the best in the world, is NOT even close to adequate to meet the needs of widespread use of natural gas vehicles. Let's take a look at this situation.

First discussing the pipeline distribution situation. The reality of the situation is that over the last 100 years the capacity built into the system was only the capacity required for heating and cooking. Average US home uses 230 cu ft per day = 83,800 cu ft/yr. Let’s say the average US driver drives 12000 miles per year. Then at 25 miles per gallon he uses 12000/25mi/gal = 480 gals/year. Now

1000 cu ft of natural gas has the energy of 7.89 gal of gasoline. Therefore, (480/7.89)*1000 = 60,836 cu ft of natural gas is needed per year (assuming the same engine efficiency). Thus the average home would need 73% more natural gas delivered to it if home filling were an important way to advance the use of natural gas before it was possible to afford building out the filling stations. But many of these homes have two cars! Thus the further dilemma: Needing another 73% more gas delivered and possibly of second home refilling unit to get both mom and dad to work the next morning. With home refilling units costing the order of $4,000 this is not a trivial expense.

With this calculation that suggests the average American household would need 73-146% more natural gas supplied to their house, we move onto pipeline capacity. To bring some reality into the situation, we must understand that the existing pipelines were built to meet the existing needs. Two quotes from the EIA site http://bit.ly/MJlv01 should put the picture into perspective; “Natural gas pipeline companies prefer to operate their systems as close to full capacity as possible to maximize their revenues…… during periods of high demand for natural gas transportation services, usage on some portions of a pipeline system may exceed 100% of certificated capacity. Certificated capacity represents a minimum level of service that can be maintained over an extended period of time, and not the maximum throughput capability of a system or segment on any given day." So current pipeline capacity is not far from peak already.

A different perspective is from The Interstate Natural Gas Pipeline Association (INGAA) 2009 report which states that natural gas usage increase by 2035:

“will require an investment of $108 to $163 billion in pipeline assets."

The cost of this ’natural’ growth in the pipeline structure is 3.75-5.67 times my estimate of converting the entire nation' vehicles to using methanol ( $28.75 billion), and the INGAA estimate DOESN”T include the scenario of home refilling, which as I indicated above would require between 73 and 146% further increase in capacity.

There are further issues with pipeline capacity at filling stations. These locations need to deal with peak hour demands. Thus, the natural gas pipeline delivery has to be sized to peak demand times, because it is impossibly expensive for service station owners to put in large high pressure storage tanks. Note if using methanol, either local methanol reactors can run overnight (spreading out the nat gas delivery rate required over a much longer time allows enough fuel to be available in the tanks at peak hours), and/or methanol can be delivered to the service stations and stored in the tanks as gasoline is delivered and stored now.

Thus the idea that the infrastructure is already in place has got to be rigorously reevaluated.

2.1.3. What if you could refuel at home, how much would it cost?

The cost of natural gas delivered to homes in the US homes is reported by Knittel ( in "The Hamilton Project Report” 2012-03 June 2012): "The high cost of natural gas delivery in homes can overwhelm the price advantage of natural gas, making natural gas artificially more expensive than petroleum. According to the U.S. Energy Information Administration (EIA), natural gas prices at the wellhead were $2.46 per thousand cubic feet in February of 2012, but the average residential price was $9.40 per thousand cubic feet. The average city gate price was $4.75 per thousand cubic feet."

He goes on to say "Utilities likely use this pricing structure to help them recover the high costs of building pipelines to distribute gas, but such a price distortion may lead to inefficiently low amounts of adoption of CNG vehicles." Thus, as we can see, the additional infrastructure needed in homes as discussed above would bring the costs well above any of the estimates made above, but they are not currently quantifiable.

The bottom line, is that although using CNG at first appears to be a good idea, and will work for fleets and other niche markets, as a national solution it would not be workable.

2.2. The Greenhouse Gas issues

Methane is 22 times as powerful a greenhouse gas (GHG) as carbon dioxide (CO2). As it is produced and used, it gets into the atmosphere primarily because it is actually just let out of both production and industrial processes, and secondarily because it must be transported under pressure and leaks are prevalent in pressurized distribution systems. We discuss this below:

2.2.1. Leaks in distribution and pumping.

2.2.2. Methane pass through the exhaust of natural gas vehicles.

2.2.3 Methane release during production and purification of natural gas.

The both leaks and the purposeful emissions result from both oil and gas production.

3. What about liquefying natural gas for commercial operations?

Using today's technology, there are aspects of our transportation structure that could benefit from using liquefied natural gas. Interestingly enough this would pertain to the very large fleet of older trucks that will need to pass emissions restrictions if refurbished.

4. Fossil Natural Gas and the Need to Use it to Build Our Transportation Infrastructure

As we have said, using natural gas directly is an inefficient use of its energy. We have about 100 years of fossil natural gas at our disposal under our feet. We should be using it now, to reduce emissions and get us of imported oil. But as we discussed above, not directly as compressed or liquefied natural gas.

Here we briefly review the the approach of the Institute, which, of course, is to look towards the overall best ways to utilize our resources to get the energy we need.

As we see it, there is a convergence of techniques, which if focused on a similar endpoint fuel, we will have the best situation. What do we mean? The fuel we see, that is a common endpoint of many renewable processes is alcohol! We discuss the performance of alcohols here and here. Clearly, they can be mixed together and thought of as one fuel - and this is a step that needs to be made by us now. It has already been made by some car companies (Fiat, Lotus) for their vehicles sold in Brazil, and earlier by Ford in the 1980's. But our purpose on this page is to simply restate that in the long term alcohols will be the most sensible, renewable, carbon neutral fuel. Here we need to discuss the short term picture, which strongly suggests that we can meet our needs to get off oil, by using both corn based alcohol (ethanol) and natural gas based alcohol (methanol). In the future we will be making ethanol from wastes, and methanol from wastes.

There are a number of modern techniques that can make bio-gas. Ranging from using our organic wastes, to producing non-food stuffs such as algae and then anaerobically digesting it, to using stranded natural gas that is often released into the atmosphere, or flared off. All these processes can contribute to an abundance of liquid alcohol fuels for our future needs.

5. Renewable Natural Gas

Renewable natural gas, which is a term used to refer to bio-gas, a mixture of methane and carbon dioxide, which has been cleaned of the carbon dioxide it contains. Bio-gas is produced all over the surface of the earth unwittingly most of the time. It results from the decay of any organic matter in the absence of oxygen, a process called anaerobic digestion. This occurs under every cow plop, in all our landfills, in many farmers fields, etc. It can be purposefully produced and collected as an energy source. In some countries, such as Germany, it has become an important factor in their energy supply.

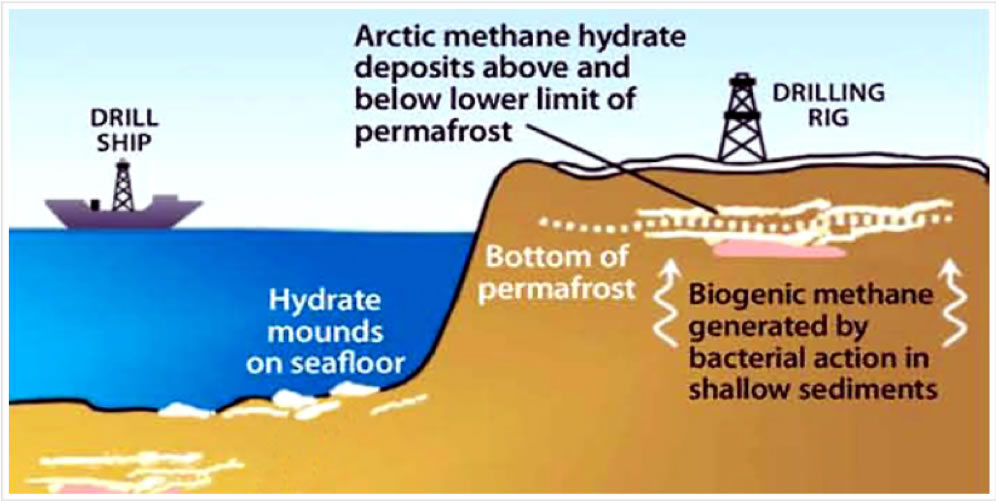

6. Natural Gas from Sea Ice

Perhaps the largest source of fossil natural gas exists in just hundreds of feet of water, along the continental shelves that surround these land masses of the world, presented in World Natural Gas. Here we talk about ways to extract it, and why we might want to extract it.

7. CARB well-to-wheel CO2 estimates

CARB, the California Air Resources Board, has done an extensive study of the carbon dioxide in the exhaust. We present their conclusions here.