Ethanol Fuels - Background and Introduction

Ethanol Fuels - Background and Introduction

Ethanol is made by distilling sugars found in vegetable matter. We are all familiar with ethanol as it is the ingredient we casually call 'alcohol' in drinks such as beer, whiskey, scotch, vodka, etc. Ethanol can also be made from cellulosic 'wastes' (wood chips, corn husks, etc.) In addition, a new technology now enables it to be made from natural gas. We discuss the current situation and the new beginnings just starting to occur commercially this year (2013). It is clear that within a decade ethanol will be made without having any influence on food stuffs.

Table of Contents

1. History of Ethanol Use in Internal Combustion Engines

1.1 Henry Ford and Ethanol

2. Modern Production of Ethanol

2.1 Ethanol from Corn2.1.1. The food vs. fuel debate

2.2 Ethanol from Sugar Cane2.2.1. Brazilian Production

2.2.2. Indian Sugar Cane Ethanol

2.3 Cellulosic Ethanol

2.4 Ethanol From Natural Gas

Top

3. Value of Ethanol in Current and Near Future US Vehicles

3.1 US EPA ethanol fuel studies3.1.1. Reformulated Gasoline Contains 10% Ethanol

3.1.2. US Ethanol Mandates

3.2 Value of using ethanol in existing 'gasoline' only vehicles3.2.1 What is story of using E15? Will you pay more to get less, or will you benefit?

3.2.2. Studies of the Effects of 15%, 20%, 30% and Higher Ethanol Addition to Gasoline in Both Flex-Fueled and Non-Flex Fueled Vehicles

3.2.2.1. The Minnesota Study and the Phenomenon of an Optimum Blend of Ethanol in Gasoline

3.2.3. A larger Minnesota Study using E20 on non-flex fueled ('gasoline only') vehicles

3.2.4. How is it possible that better mileage can be obtained?

3.2.5. Need for an ethanol 'performance' map for each vehicle

3.2.6. Can a 'Gasoline Only' Vehicle use these higher blends?

3.2.7. How can we transition to blends of Alcohols in our current E85 Vehicles?

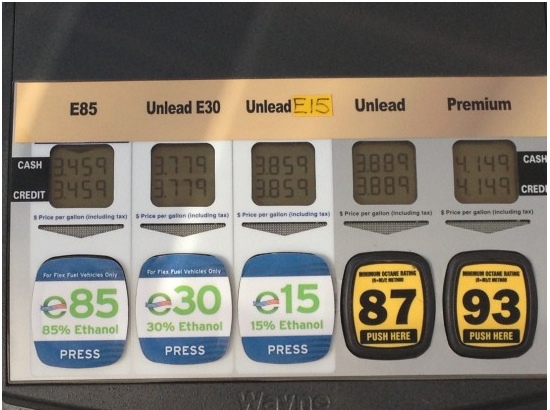

3.2.8. Distribution via Blender Pumps

4. Flex Fueled Vehicles in the US and the Options Around the World

4.1. What can an ethanol engine do?

4.2. Flex fueled vehicles in Brazil

4.3. Flex Fueled vehicles in Europe

4.3.1. Saab

4.3.2. Ricardo

4.4. Flex Fueled Vehicles in the U.S.

4.5. Auto Racing in the US

5. Potential of Ethanol

5.1. Power and Mileage Potential

5.1.1. Thermal Efficiency

5.1.2. Fuel Consumption

5.1.3. Reasons for the Improvements

5.1.3.1. Charge Cooling Effects

5.2. Holding RON Constant at 93 Reduces the Value of Ethanol Blends

5.3. Hydrous vs. Anhydrous Ethanol in IC Engines

5.4. Distribution and Storage of Hydrous and Anhydrous Ethanol

5.4.1. Brazilian Pipelines

6. The Emissions Reduction Potential of Ethanol in IC Engines

7. Carbon Dioxide Emissions from Ethanol Plants

7.1. US plants

7.2. Brazilian plants

8. Water and Fertilizer Usage

8.1. US

8.1.1 Water Usage

8.1.2. Fertilizer Usage

8.2. Brazil

8.2.1. Water Usage

8.2.2. Fertilizer Usage

9. Dry Land Ethanol Production

9.1. Water Efficient Crops

9.2. Water Conservation in Ethanol Processing

10. Emissions from existing vehicles using Ethanol Blends

10.1. Tests on existing vehicles using ethanol blends higher than E10

10.1.1. No operational issues

10.1.2. Emissions and fuel economy

10.1.2.1. Fuel economy from two test series

10.1.2.2. Emissions from two test series

11. Refineries adjust the octane number downward

11.1 Refineries holding octane to old levels11.2. Key value of higher octane.

11.2.1. How alcohols can get better mileage

11.2.1.1. What is the octane rating of various ethanol blends?

11.2.1.2. Effect of Ethanol on Knock

11.3. Current Reformulated Gasoline limits ethanol's value