Refineries and Their Position on Octane Levels

The information below, is complimented by a separate section on the "The Potential of Ethanol in IC Engines" link to it here.

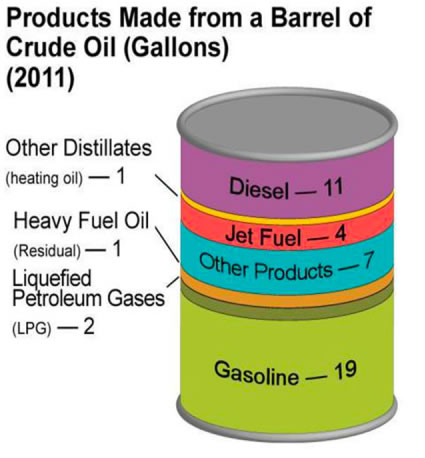

A barrel of oil (42 gallons) is separated into various constituents at the refinery.

The proportions are shown below.

1. Refineries holding octane of E10 to old levels.

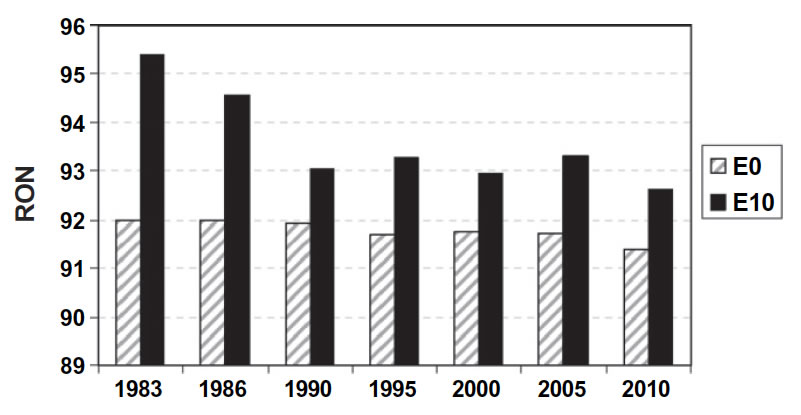

According to Ford's J.E. Anderson et al., "the refining industry has adapted their blending practices by creating blendstocks for oxygenate blending (BOBs) for E10 that have considerably lower octane rating than a similar grade of finished gasoline lacking ethanol (E0). The adoption of this approach is seen in Fig. 3, summarizing survey data from US retail filling stations, specifically for measured octane ratings of unleaded regular-grade fuel identified as 92 RON at the pump."

"Octane ratings above the minimum shown on the pump label are termed octane ‘‘give-away’’ by the oil industry (but could provide a benefit to the consumer). With E10 in 1983, the octane ‘‘give-away’’ occurred because ethanol volumes were small (E10 comprised less than 4% of regular-grade fuel based on Fig. 1 data). At these volumes, refineries would have found it impractical (and not cost-effective) to make small quantities of a lower-octane-rating blendstock for E10; thus the ethanol was likely ‘‘splashblended’’ into the prevailing regular-grade E0 gasoline."

By 1990, the average octane ratings of regular-grade E10 had decreased considerably and remained essentially unchanged through 2010 this change reflects the adaptation of refining and blending practices to the E10 ethanol content by mixing it with blendstocks that had lower octane ratings (this clearly costs them less).

Figure 1

"High octane number ethanol-gasoline blends: Quantifying the potential benefits", Anderson et al. 2012 Fuel

In Section 3, below, we give more details on why doing this completely removes the value that we could be getting from the additional ethanol.

2. A key value of higher octane - a way to increase mileage

As we see the refineries have conditioned their output to give only marginal increases in octane over the mandated overall octane rating of RON of 92. As the Ford engineers point out "...it is clear that higher octane rating fuel

presents two main opportunities for higher efficiency: modest

gains from spark-advance technology in today’s engines and larger

gains from higher CR and/or further turbocharging and downsizing

in future engines." In our chapter on 'the value of ethanol..." we focus on the wide variance in mileage that occurs with higher ethanol blends when neither of the above changes have been made. Even on existing vehicles, their can be an increase in performance and mileage with higher blends. It is clear, however, that "For the 88- and 92-RON blendstocks,

the evaporative cooling from the ethanol is estimated to provide

about 25–35% of the total octane number (ON) increase in the blend relative to

the blendstock.

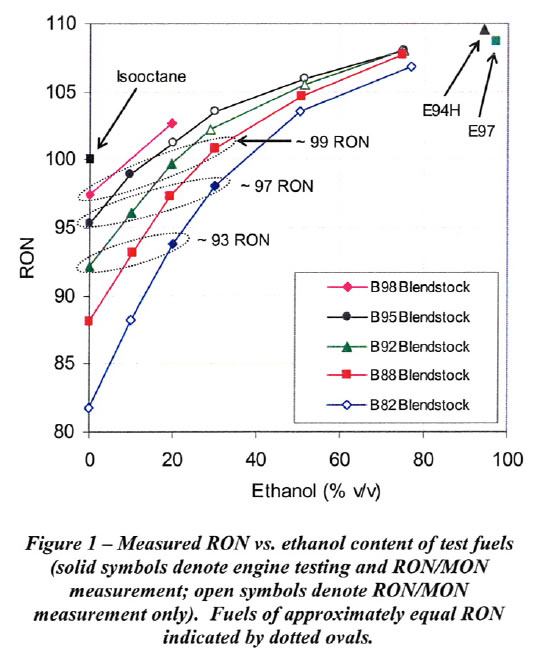

"If ethanol content is increased above E10 in the future, then the additional ethanol could be used to increase the RON of the resulting ethanol–gasoline blend (Fig. 5). If the blendstock is maintained at 88 RON (i.e., no change from 2010), then the RON of these higher ethanol–gasoline blends could be increased to an estimated 94.3 for E15, 95.9 for E20, 97.4 for E25, and 98.6 for E30 (as compared to 92.5 RON for E10)."

For most LDVs on the road today, fuel with higher octane ratings

would provide modest improvements in fuel consumption

[31]. Nearly all modern spark-ignited engines are equipped with

knock sensors and adaptive spark control, allowing the engine to

adjust to the octane rating of the fuel under actual operating conditions.

Fuel with greater knock resistance allows earlier (more advanced)

spark timing at high loads, which improves engine

efficiency. Earlier spark timing also reduces exhaust temperature

and thus less enrichment is required for component protection at

high engine speeds, providing an additional efficiency improvement

(modern engine control systems use sophisticated algorithms

to minimize enrichment based on inferred exhaust

temperature).

2.1. How alcohols can get you better mileage

Coordination of increases in engine CRs and gasoline octane ratings would represent a resumption of earlier historical trends. With the exception of the World War II years, the octane ratings of regular-grade gasoline in the US increased steadily from 1930 (60 RON, 60 AKI) until the early 1970s (94 RON, 90 AKI) [19,20]. Since that time, gasoline octane ratings have remained steady or even declined somewhat [21]. Meanwhile, the average CR of gasoline engines in the US increased from approximately 5 in 1930 to 10 in 2008 [16]. Past increases in CR were enabled by a combination of increased octane ratings in gasoline (initially) and advances in engine technology (e.g., knock control through adaptive spark control, variable cam timing, direct injection). Today, new naturally-aspirated (non-turbocharged) gasoline engines in the US typically have CRs in the range of 10–11, with higher CRs for DI engines than for PFI engines, and somewhat lower CRs for turbocharged engines.

If we made fuel with greater ethanol content with no change in the prevailing 88-RON blendstock (Fig. 5) would enable further compression ratio (CR) increases. Relative to the 89-RON E0 baseline, increases of 1.0, 2.0, and 2.9 CR in DI engines are estimated for E10, E20, and E30, respectively, which includes the cooling ON effect.

The key conclusion is that engine thermal efficiency improvements for the scenarios above are expected to be on the order of 2–5% for the above scenarios. Thus, fuel consumption is reduced by 2–5%.

2.1.1. What is the octane rating of various ethanol blends?

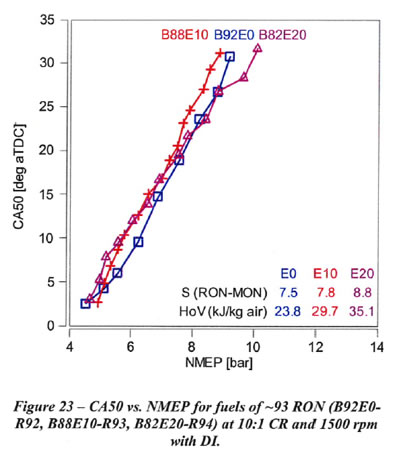

It is clear from the plot below that as the percentage of ethanol is increased in a blend with gasoline, that the Research Octane Number (RON) is increased. Of special interest is the fact that the increases are most rapid for E10, E20 and E30. This paper by Stein et al 2012 SAE 2012-01-1277 is an important source of information on the effects of ethanol on engine performance.

2.1.2. Effect of Ethanol on Knock Limit with Direct Injection

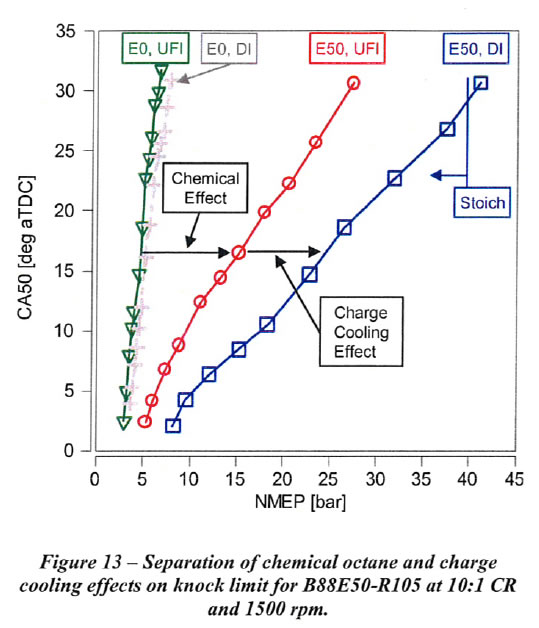

The work of Stein et al 2012 also investigated the change in knock limit. The testing procedure for his plot is discussed on our page The Potential of Ethanol in ICE.

They state that "If the fuel is assumed to be fully vaporized before it is inducted into the cylinder for UFI ("upstream fuel injection"- UFI is pre-vaporized and simulates carbureted fuel intake), then knock is affected only by the chemical octane of the fuel. In contrast, Direct Injection (DI) will provide the maximum charge cooling effect due to fuel vaporization in the cylinder. Therefore, knock for Dl will be affected both by the chemical octane of the fuel and its HoV. The situation with port fuel injection (PFI) is less clear, as some vaporization of the fuel occurs during the intake stroke, especially with OVI. Thus for PFI the HoV of a fuel is anticipated to have an effect on knock which is between that of UFI and DI. The reduction in charge temperature due to vaporization of the fuel with Dl was estimated using the GCA model. This model incorporates gradual vaporization of the fuel in the cylinder during the intake and compression strokes, and also assumes a fraction of the heat of vaporization comes from the piston and cylinder walls, based on experience at AVL with Dl engines. With this fuel, DI results in approximately a 30 deg C reduction in charge temperature.

Separation of the chemical octane and charge cooling effects on the knock-limited NMEP for E50 compared to E0 with 88 RON gasoline blendstock is shown in Figures 13 (above) for 1500 rpm. The knock-limited NMEP increase from UFI with E0 to UFI with E50 is attributed solely to the higher chemical octane of E50, since it is assumed that the fuel for UFI is fully vaporized. The knock-limited NMEP increase from UFI to Dl for each fuel is attributed to charge cooling due to vaporization of the fuel in the cylinder with Dl. Charge cooling results in a small increase in NMEP for E0. The increase for E50 is much greater than for E0 as a consequence of the higher HoV and sensitivity of E50 compared to E0."

3. Why Refinery's Reformulated Gasoline (RBOB), which is blended so that the overall octane remains constant, does you little good!

The additional octane that ethanol can result in do to its rapid evaporation, is completely lost in Reformulated Gasoline in which the blendstock octane is reduced so as to make the total octane achieve the minimum standard. As we show above, in Stein's Figure 13, the 'added octane' due to the more rapid evaporation of ethanol is completely absent. Thus the changes refineries made, see Figure 1, really do hurt our chances of using all of the value that ethanol can provide.